With the current advancement in flooring technology, people in the home and their businesses can have a variety of choices, unlike in the past. Some of the most widely contrasted solutions that exist today are SPC flooring and laminate flooring, which are both aimed at the appearance of the natural sources but also have the benefits of being practical in terms of price and functionality.

In as much as they might be seen as the same thing, SPC and laminate flooring have a lot of differences based on the materials used, the way they are made, longevity, and their actual life performance. When choosing an appropriate floor to prefer, it is important to know such differences. This article pits SPC and laminate flooring against each other on several of the most important factors and assists you in deciding which of the two would suit your needs, environment, and long-term expectations better.

1. Different Raw Materials

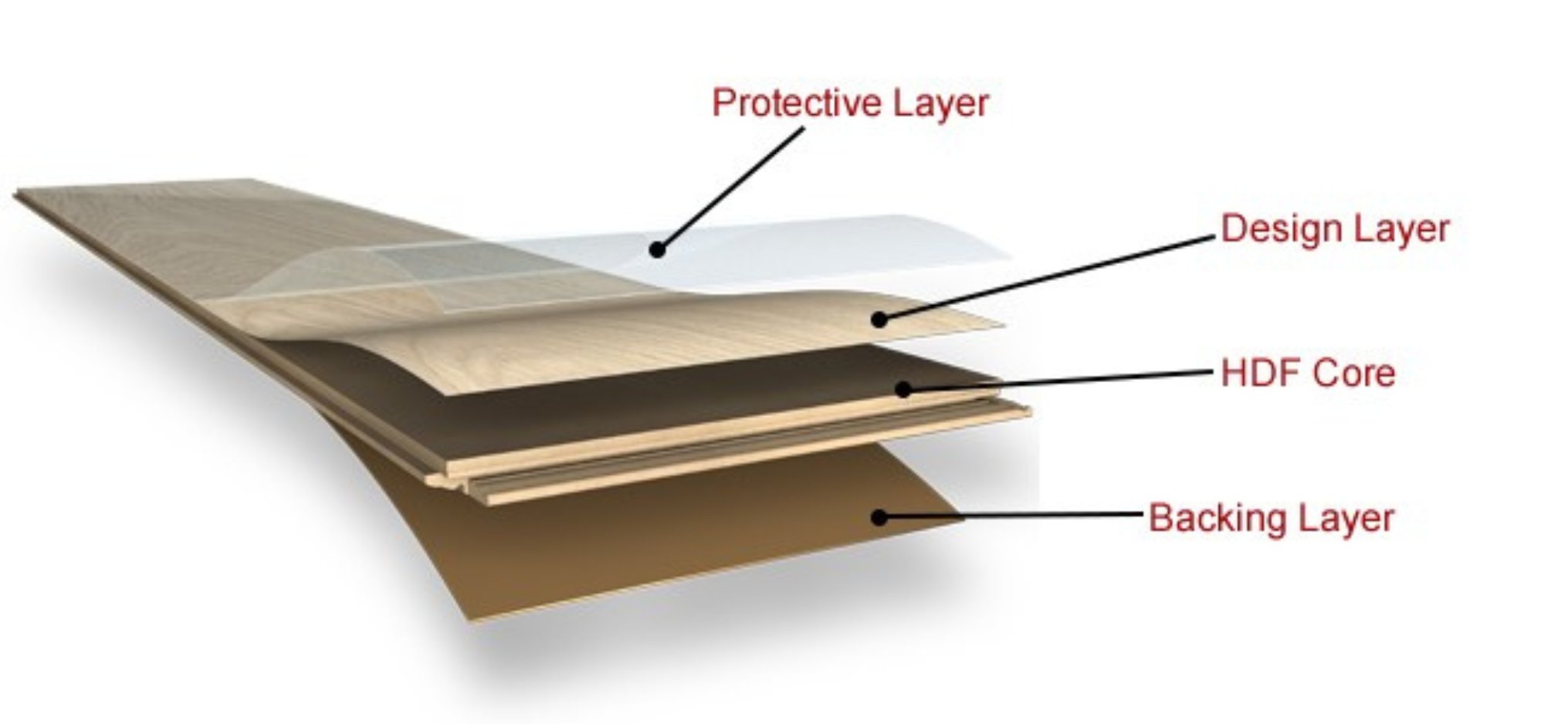

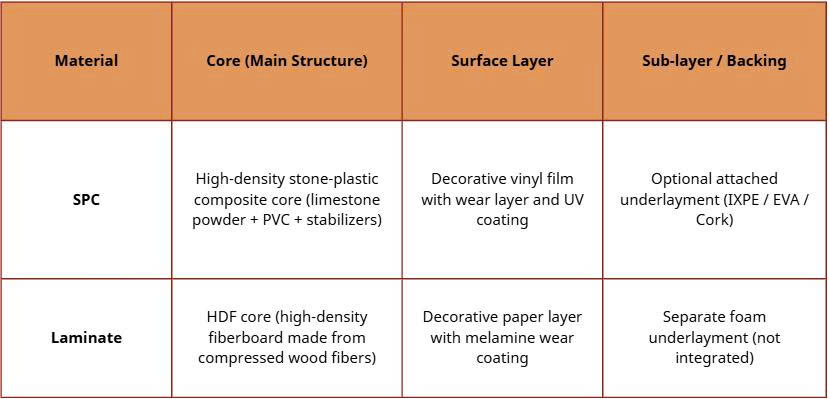

It is important to understand the essential materials of each of the types of floors before comparing their performance. The structure of the SPC and laminate flooring determines its durability, resistance to moisture and long-term stability, as can be demonstrated in the following table.

2. Different Production Processes

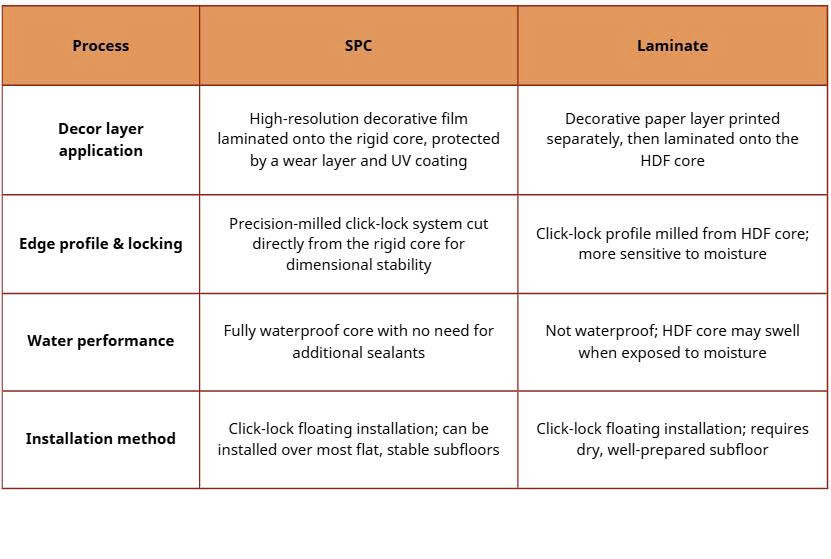

The SPC vinyl is produced by an extrusion process. Once the raw materials are completely mixed, they will be directly extruded together with the color film layer and the wear-resistant layer by using the extrusion production line. The basic principle to be observed in this process is that the energy produced by high temperature is to be used, and no glue products are needed in the process.

Besides, laminate wood flooring is produced by the process of hot pressing. A high-temperature pressing machine with a 170–210°C core material, color film layer, and wear-resistant layer is loaded with the balance paper, and finally, the pressure of 18 to 23 MPa is applied to shape the board.

Along with the fundamental forming processes, SPC and laminate flooring additionally vary in various production phases afterwards which directly affects the product stability, moisture, and performance in installation.

3. Different Product Characteristics

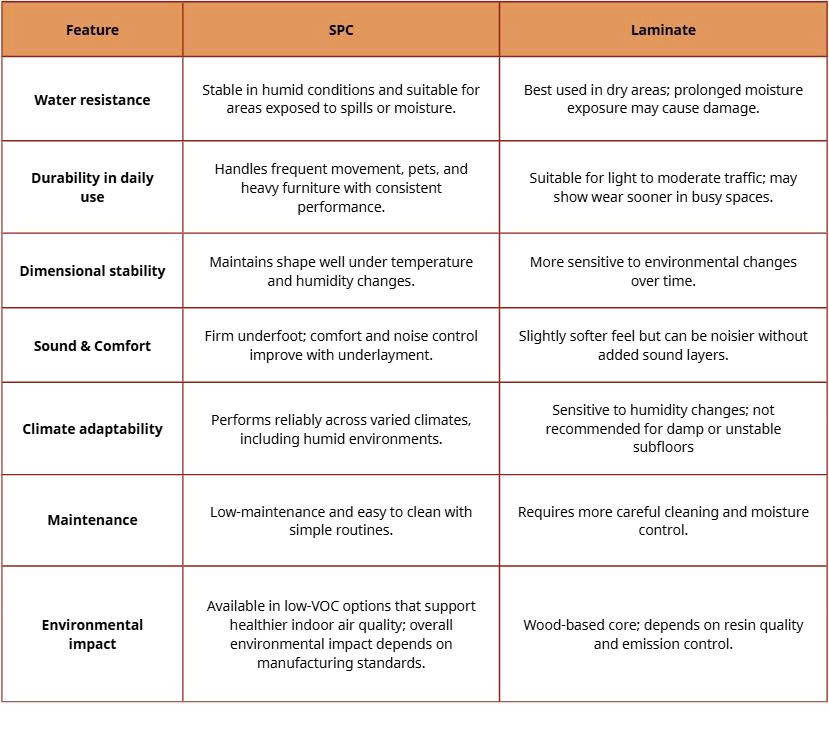

The performance of the products reflects the variations in materials and manufacturing procedures. The table below illustrates the differences in durability, water resistance, comfort, maintenance, and overall appropriateness between SPC and laminate flooring.

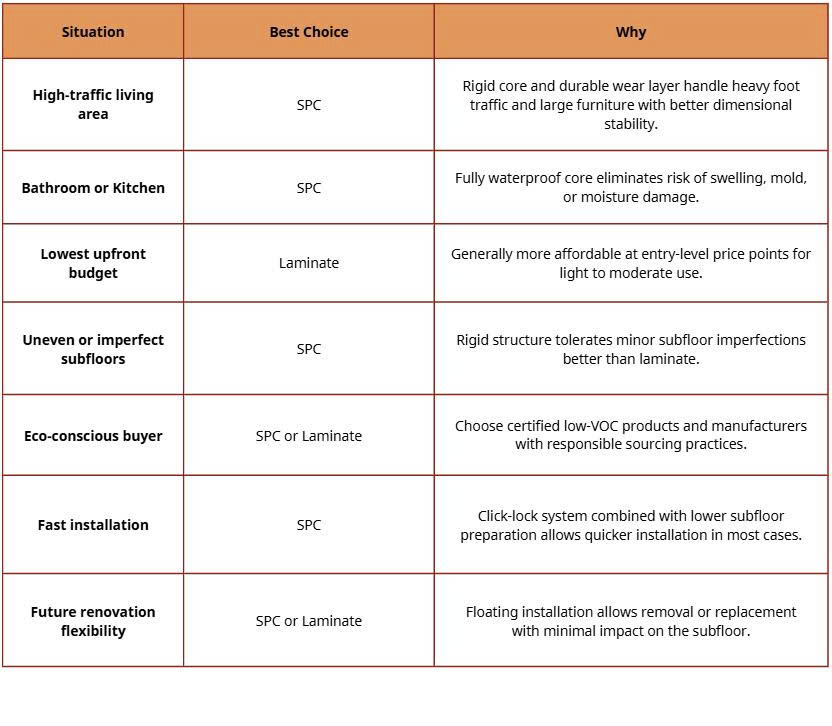

4. Which is Better? (Depends on Your Demand)

When deciding between the use of SPC or laminate flooring, there is no general answer, given the differences in the answers. The optimal choice will require consideration of elements like the usage, environment, financial resources and expectations in the long term. The following table can be used to shed light on the types of floors that will be most appropriate in your circumstances.

In conclusion,

SPC and laminate flooring are used in the diagnosis of various laying purposes. Although laminate may be an appropriate flooring in dry and light-traffic areas, SPC flooring is more stable and resistant to moisture and long-term performance, so it is a more stable choice to use in contemporary homes and businesses.

VN ECOFLOOR should be consulted via Hotline/WhatsApp: +84 88 801 81 28 in case you need to source SPC flooring in bulk or OEM manufacturing solutions. Having more than 15 years of manufacturing and export experience all around the world, VN ECOFLOOR is considered one of the leading OEM manufacturers of floors in Vietnam, which helps the partners globally to deliver quality products and produce them in variable quantities. See us at https://vnecofloor.com/.